We have been developing clamping systems of high quality and precision for over 30 years. Already in the planning and development of expansion shafts, expansion mandrels, expansion chucks and friction shafts we rely on know-how and professional competence.

Many years of experience, technical know-how and adherence to delivery dates distinguish us as a high-performance partner in clamping technology.

Information on the prices of our products is available on request.

Read morepneumatically actuated

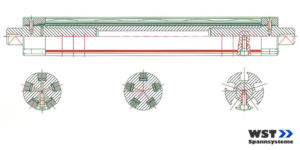

Each SWY expansion shaft is calculated and designed by us according to the customer’s technical data, such as torque transmission, deflection and maximum load of the expansion shaft. We manufacture the bearing journals individually according to customer specifications.

With a filling gun the compressed air is pressurized with approx. 6 bar through the radially or axially arranged filling valve into the external flat hoses, whereby the continuous clamping bars are pressed against the winding core.

This means that several narrow winding cores of different widths can be clamped. When venting, the tensioning bars slide back into the grooves through the installed springs, so that the panels can be easily removed. If the SWY expansion shaft is equipped with pre-centering bars, the winding core is automatically aligned along the expansion width. The release of two clamping pieces makes it easy to pull out the clamping bar and hose.

The SWY expansion shaft is available for winding cores with an inner diameter of 70-400 mm. On request, this expansion shaft is also available in other dimensions.

pneumatically actuated

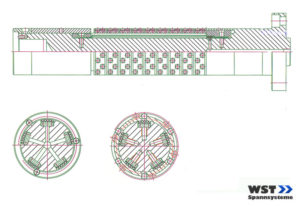

Depending on bale weight, bale width and torque, the support tube is equipped with a number of independently operating clamping elements.

The filling valve fills the internal rubber hose with approx. 6 bar air so that the clamping elements are pressed outwards.

In order to prevent the various types of cores from slipping through, clamping elements made of different materials with longitudinal or transverse grooves are used.

The support tube can also be made of steel, aluminium or carbon fibre reinforced plastic.

The SWX expansion shaft is available for winding cores with an inner diameter of 50-150 mm. On request, this expansion shaft is also available in other dimensions.

Friction shaft, pneumatically adjustable, centrically clamping

Die auf der hartverchromten und geschliffenen Trägerwelle installierten Friktionsringe spannen die eng tolerierten und harten Kartonhülsen durch eine kurze Drehung in Laufrichtung.

Eine fixierte Luftzuführung versorgt die Flachschläuche mit der benötigten Druckluft. Die Druckluft variiert von 0-7 bar, abhängig von Rollendurchmesser und vorgegebenem Bahnzug. Hierdurch werden die darüberliegenden Reibbeläge gegen die Innenringe der Friktionskörper gepresst. Die somit erzeugte Reibkraft überträgt das erforderliche Drehmoment auf die einzelnen aufzuwickelnden Rollen.

Um gleichmäßiges Aufwickeln bzw. Durchrutschen der Rollen zu erzielen, muss die Friktionswellendrehzahl bis zu 5 {674e15ad354879ac26cb6e8a2d34ac113c44736b412a6a0f02c07b6a650b14c7} Voreilung gegenüber der Bahngeschwindigkeit aufweisen.

Nach einer kurzen Drehung in Laufrichtung können die fertig aufgewickelten Rollen leicht abgezogen werden.

Die Friktionsspannwelle FSW ist für Wickelhülsen mit einem Innendurchmesser von 50-305 mm lieferbar. Auf Wunsch ist diese Spannwelle auch in anderen Abmessungen erhältlich.

pneumatically actuated

With a filling pistol the compressed air is forced axially or radially through the filling valve at approx. 6 bar or through a stationary air supply into the external flat hoses. By pressing the clamping bars outwards against the cutting bushes, lateral displacement or slippage of the cutting bushes is prevented.

With a filling pistol the compressed air is forced axially or radially through the filling valve at approx. 6 bar or through a stationary air supply into the external flat hoses. By pressing the clamping bars outwards against the cutting bushes, lateral displacement or slippage of the cutting bushes is prevented.

The shaft body of the dynamically balanced lower blade shaft is hard chrome-plated and ground to the inner diameter of the cutting bush with a small tolerance so that the lower blades can be easily moved.

The UMW expansion shaft is available for winding cores with an inner diameter of 70-400 mm. On request, this expansion shaft is also available in other dimensions.

pneumatically actuated

Clamping wedges are pressed outwards centrically from the support tube. Due to a favourable power transmission, large weights can be tensioned in the self-locking area, if necessary with power transmission and spring tension.

Clamping wedges are pressed outwards centrically from the support tube. Due to a favourable power transmission, large weights can be tensioned in the self-locking area, if necessary with power transmission and spring tension.

Depending on bale weight, bale width and torque, the supporting tube is equipped with a number of clamping elements.

It can be made of steel, aluminium or carbon fibre reinforced plastic.

The pistons are made of aluminium or steel and have special seals.

The clamping mandrel SDZ corresponds to the clamping width of the type SWL, but is mounted on one side.

The expansion shaft SWL is available for winding cores with an inner diameter of 70-150 mm. On request, this expansion shaft is also available in other dimensions.

pneumatically actuated

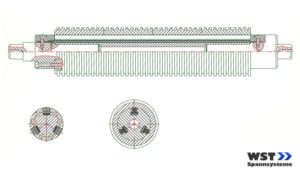

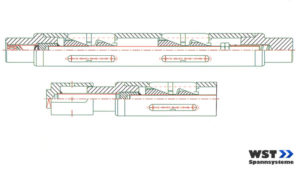

With the aid of a filling pistol the compressed air is forced into the cylinder chamber at approx. 6 bar through the radially or axially arranged filling valve.

With the aid of a filling pistol the compressed air is forced into the cylinder chamber at approx. 6 bar through the radially or axially arranged filling valve.

Due to the axial displacement of the pneumatic piston, the piston rod penetrates into the hydraulic chamber. The hydraulic fluid displaces the hydraulic piston, which displaces a threaded rod fitted with wedge guides, so that the clamping wedges are pressed centrally outwards against the winding core via an inclined plane. The height of the clamping wedges arranged on the circumference can be adjusted in sets by means of the wedge guides with internal threads.

The centric clamping of the winding core is made possible by the uniform expansion of the clamping wedges.

When the cylinder chamber is vented, an opposing compression spring pushes the threaded rod with the wedge guides on it and the tensioning wedges fitted with torsion springs back into their initial position. The winding core is now relaxed and the expansion shaft can be pulled out of the roll.

The expansion shaft LZW is available for winding cores with an inner diameter of 70-400 mm. On request, this expansion shaft is also available in other dimensions.

mechanically operated

The clamping elements, which can be moved on the carrier shaft, are spread by means of cones guided in the shaft grooves with a hook wrench. The clamping elements are then adapted to the winding core length by offsetting the spacer sleeves.

The diameter of the carrier shaft and the number of clamping elements depend on the weight and arrangement of the material bales used.

For the use of different winding core diameters, interchangeable clamping cores with a diameter of 68-400 mm are available.

mechanically operated

With the help of a socket wrench, the internal clamping screw is operated manually, so that the clamping wedges are pressed mechanically centrically against the pushed on winding cores over an inclined plane.

With the help of a socket wrench, the internal clamping screw is operated manually, so that the clamping wedges are pressed mechanically centrically against the pushed on winding cores over an inclined plane.

The wedge guides are moved axially in the support tube by means of a threaded spindle. When the tension is released, the inner parts are pushed back into their initial position by a compression spring. The clamping wedges also return to the zero position via spring pressure.

We manufacture the bearing pins individually according to customer specifications.

Various attachable clamping wedges made of rubber, aluminium or steel with longitudinal grooves are used for different types of winding cores.

The SWM expansion shaft is available for winding cores with an internal diameter of 70 and 76 mm.