We have been developing clamping systems of high quality and precision for over 30 years. Already in the planning and development of expansion shafts, expansion mandrels, expansion chucks and friction shafts we rely on know-how and professional competence.

Many years of experience, technical know-how and adherence to delivery dates distinguish us as a high-performance partner in clamping technology.

Information on the prices of our products is available on request.

Read morepneumatically actuated

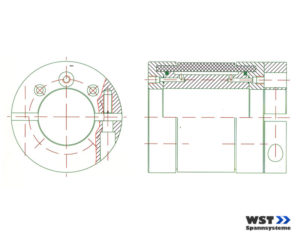

With a clamping range of 148-158 mm, the expansion couplings are pushed and clamped in pairs onto an existing expansion shaft, e.g. type SWX, SWY or onto a bare carrier shaft, depending on the winding core width.

Depending on the diameter of the expansion shaft or carrier shaft, the clamping shells can be turned out from 40-75 mm as standard. Special sizes are available on request.

Depending on the diameter of the expansion shaft or carrier shaft, the clamping shells can be turned out from 40-75 mm as standard. Special sizes are available on request.

A compressed air gun fills the coupling with 5-7 bar through the radially or axially arranged quick exhaust valve. Several couplings can be connected to each other via a spiral hose, so that the air only has to be supplied on one side.

mechanically operated

The clamping couplings SK are generally mounted and fastened on existing carrier shafts, whereby they can be positioned axially freely. The clamping of the interchangeable clamping sleeves is carried out with the aid of a hook wrench or a knurled nut. This makes it possible to drive winding cores with large diameter tolerances on a clamping coupling.

If winding cores with different diameters are to be used, interchangeable clamping cores up to a diameter of 400 mm can be supplied.