We have been developing clamping systems of high quality and precision for over 30 years. Already in the planning and development of expansion shafts, expansion mandrels, expansion chucks and friction shafts we rely on know-how and professional competence.

Many years of experience, technical know-how and adherence to delivery dates distinguish us as a high-performance partner in clamping technology.

Information on the prices of our products is available on request.

Read morepneumatically actuated

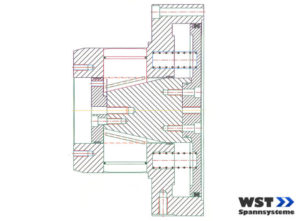

Conical clamping wedges with maintenance-free coating integrated in the chuck housing are pressed outwards pneumatically (SPL chuck) or mechanically (SPM chuck) with the aid of a favourable power transmission.

This tensions the material bale in the self-locking area.

This tensions the material bale in the self-locking area.

The SPL chuck can be filled with air either axially through the shaft or radially at the chuck.

The cylinder connection dimensions are designed as a function of the bale weight and the torque.

Depending on the application, the pistons can be made of aluminium or steel, using special seals. Clamping wedges located in the clamping head housing are secured against ejection.

In order to clamp larger winding core diameters, it is possible to slide adapters onto the chuck head.

The SPL chuck is available for winding cores with an inner diameter of 70-400 mm. On request, this chuck is also available in other dimensions.

Translated with www.DeepL.com/Translator

pneumatically actuated

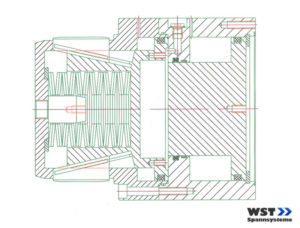

The radial or axial compressed air supply of approx. 6 bar displaces the pneumatic piston and the wedge guide in axial direction. In this way, the clamping wedges are pressed centrally outwards over an inclined plane against the winding core, thereby transmitting the required torque.

After venting, the wedge guide is pushed back to its initial position by a compression spring or the tension wedges by a leg spring. Depending on the winding core material, the surface of the tension wedges is either rubberized or made of steel with longitudinal grooves.

The expansion of the clamping head can also be effected by a push rod.

In order to clamp larger winding core diameters, it is possible to slide the adapter onto the expansion chuck.

The LSK chuck is available for winding cores with an inner diameter of 70-400 mm. On request, this chuck is also available in other dimensions.

Translated with www.DeepL.com/Translator

pneumatically actuated

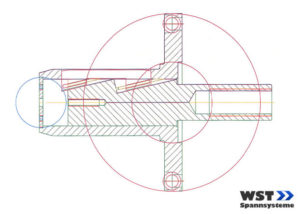

This clamping head guarantees absolute clamping safety due to spring preload. The spring assembly is preloaded by means of a pneumatically driven piston and a hydraulic power transmission, whereby the clamping rows reach their smallest diameter. After pushing on the material bale or the winding core, the air is released and the spring force tensions the wedges.

In order to clamp larger winding core diameters, it is possible to slide the adapter onto the clamping head.

The clamping head SPS is available for winding cores with an inside diameter of 70-400 mm. On request, this chuck is also available in other dimensions.

Translated with www.DeepL.com/Translator

mechanically operated

Conical clamping wedges with maintenance-free coating integrated in the chuck housing are pressed outwards pneumatically (SPL chuck) or mechanically (SPM chuck) with the aid of a favourable power transmission. This tensions the bale of material in the self-locking area.

The cylinder connection dimensions are designed as a function of the bale weight and the torque.

Depending on the application, the pistons can be made of aluminium or steel using special seals. The thrust pieces in the clamping head housing are secured against ejection.

In order to clamp larger winding core diameters, it is possible to slide adapters onto the expansion chuck.

The SPM chuck is available for winding cores with an inner diameter of 70-400 mm. On request, this chuck is also available in other dimensions.

mechanically operated

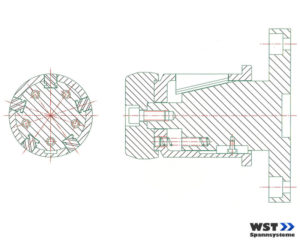

The clamping head flange is screwed to the existing shaft flange. The sleeve collar of the expansion chuck is axially displaced by the winding core to be clamped and the thrust force to be applied by the system. The clamping wedges are thus pressed centrically against the core on the fixed wedge guide.

To avoid premature expansion, the chuck can be equipped with a fixed centering lug.

The axial thrust force determines the torque to be transmitted.

The ASK chuck is available with a diameter of 60-400 mm.

On request, this chuck is also available in other dimensions.